01 PRODUCTION AND TECHNOLOGY

Cleo Schreibgeräte Limited is an acknowledged and competent industrial supplier for the writing instrument, watch and jewelry sector for decades.

We manufacture exclusively in our factory in Bad Wilsnack/ Germany. Hence we can ensure our customers the highest quality that we can offer and guarantee that our products are truly “made in Germany”.

Cleo Schreibgeräte GmbH is certified according to DIN EN ISO 9001.

02 INJECTION MOLDING

Parts of precious resin with high requirements regarding the material and surface quality are produced in a thermoplastics processing in our company Cleo. For this workmanship we are using injection molding machines of the typ ENGEL and ARBURG.

If required we can also provide the chipping or polishing of the produced thermoplastic parts to achieve an appealing surfaces. The polishing can be done by hand or with optical profile polishing machines.

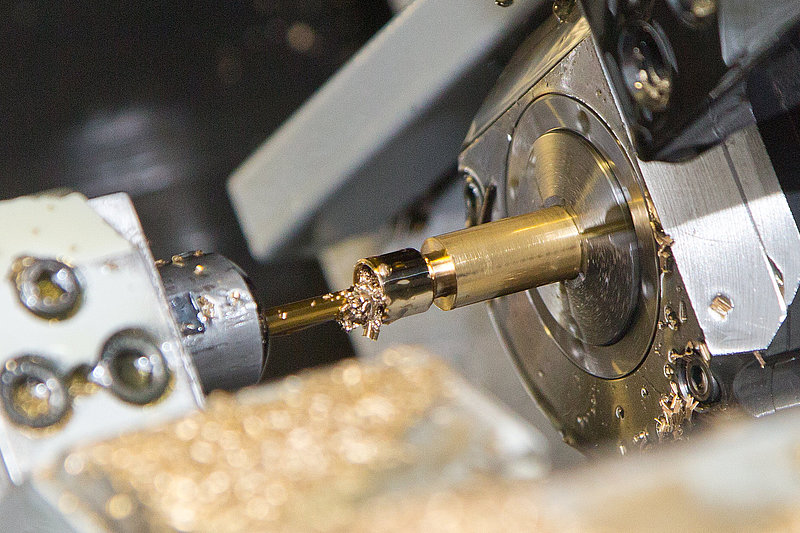

03 CNC CHIPPING TECHNOLOGY

Our main focus is the production of complex precision turned and milled parts for the writing instrument, watch and jewelry sector.

For processing are available 5-axis-milling machine, precision lathe and long turning machines.

Subsequently the parts can be chipped, trimmed, grinded and polished if required.

04 TOOL SHOP

Our department for tool making can offer the following services:

- tool making plus maintenance and repair service of tools

- jig making

- internal and external circular grinding, surface grinding

- sink erosion

05 ELECTROPLATING FINISHES

Our electroplating department is specialized in partial coating or bicolored plating of high-quality jewelry parts and ornaments. During this process only partial areas of jewelry, watchcases or writing instruments are plated with rhodium or gold with the result that several pictures can be colored in different colors. One of the most famous applications of this process is the bicolored nib in writing instruments.

Our electroplating department is grading up and protecting your items with a rhodium coating. Especially tarnishing of silver can be prevented with this plating.

06 SURFACE TECHNOLOGY AND ASSEMBLY

We can offer a wide range of completion from semi-finished goods to finished products in our department for assembly. Semi-finished goods are mounted with mechanical joining. A special service in this production process is bonding with dosing equipment or press fit assembly with the help of pneumatic devices. We could develop a pool of knowledge and experience in assembling small and ultra-small parts during decades of manufacturing high class writing instruments.

The quality specialists are supervising each production step and assuring the compliance of the defined requirements.

07 PACKAGING

Cleo is offering the possibility of packaging your goods. It is also possible to shrink-wrap goods in shrink tunnel or blister packaging which is done with machines of the company ILLIG.